In the valleys due to the angle typically produced at the valley and the use of transition flashing it is essential that the purlins are doubled in the valleys that is two purlins side by side on each side of the angle of the valley.

Purlin spacing for corrugated roofing nz.

It often depends on the wideness thickness and the types of roofing materials the climate it has to withstand and many other factors.

The overlaps ends and sides depends upon the sloop of the roof see below.

Self supporting roofing underlays designed to span between purlins where the purlin spacing is not more than 1200 mm.

Restricted access roof expect occasional foot traffic educated to walk only on the purlin lines in the profile pans or carefully across two profile ribs.

Good ventilation will also minimise 3.

For walls nogging spacings shoud be no more that 1200mm.

For the lighter material such as lightweight aluminum the common spacing length is 4 inches of clear gap.

Corrugated sheet roofing material is widely available and easy to use.

Minimum purlin size will vary according to span.

When a combination of sheets provide a run of in excess of 40 metres and up to 60 metres the roof pitch should be increased by 1 degree.

No congregation of foot traffic expected.

For the greca profile 900mm first and last and 1200mm for the intermediates.

Unrestricted access roof expect regular foot traffic to access the roof for maintenance work and able to walk anywhere on the roof.

Doubling up in the valleys refer to the installation manual for the proper on center spacing and be sure that the purlin is attached to the roofing truss.

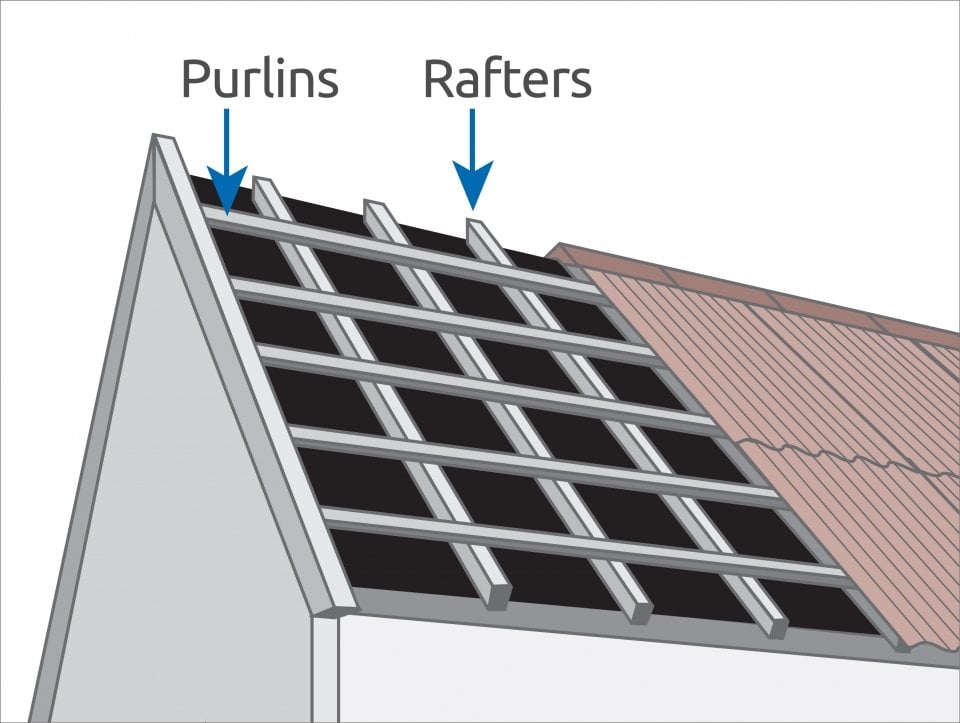

Z purlins are connected to the rafters using cleats.

Corrugations should run in a straight line between the highest and lowest points and at a right angle to the purlins the intermediate supports.

For curved structures the maximum pulin spacing should be 750mm and a minimum and 14000mm for 5 rib profile.

The minimum roof pitch for corrugate is 8 degrees approx 1 7 and if end lapped 10 degrees approx 1 6.

Longer lengths require specific design.

Or ultimate loads in respect of clip fastened products ultimate loads can be converted to serviceability loads if necessary by applying a factor of 71 in all parts of the country.

They are a breather type material consisting of bitumen saturated heavyweight kraft paper or fire retardant solvent free laminated two layers reinforced heavyweight kraft paper coated with a water based water repellent.

Patterns should be based on a given wind speed ask them for a roof plan giving purlin spacing and serviceability design loads.

All purlin joints must be supported by a rafter.

Purlin spacing should suit the end laps required for the size of sheet to be used.

For heavier material such as gage steel the metal roof purlins spacing length could go up to 4 feet.